The design of a wet wipes manufacturing machine plays a crucial role in ensuring ergonomic considerations for operators, promoting their safety, comfort, and efficiency during operation.

Here are several ways in which machine design contributes to ergonomic considerations:

- Accessible Controls: Machine controls, interfaces, and operating panels are positioned at ergonomic heights and angles to facilitate easy access and operation for operators. Controls are intuitively arranged and labeled to minimize reach and strain while adjusting settings or initiating production cycles.

- Adjustable Workstations: Workstations and platforms are adjustable in height, tilt, and orientation to accommodate operators of different heights and preferences. Adjustable features allow operators to optimize their working posture and reduce discomfort or strain associated with prolonged standing or repetitive motions.

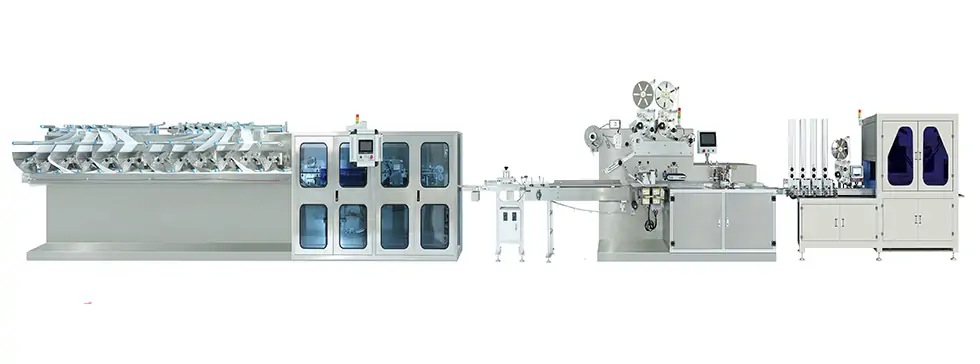

- Clear Line of Sight: Machine design prioritizes maintaining a clear line of sight for operators to monitor production processes, observe equipment status, and identify potential issues or hazards. Transparent guards, windows, or viewing panels provide visibility into critical machine components without compromising operator safety.

- Reduced Noise and Vibration: Wet wipes manufacturing machines are designed to minimize noise and vibration levels generated during operation, creating a more comfortable working environment for operators. Soundproofing materials, vibration dampening mechanisms, and isolation mounts help mitigate noise and vibration transmitted to operators.

- Ergonomic Seating: If operators are required to sit during certain tasks or stages of operation, ergonomic seating options are provided to support proper posture and minimize strain on the back, neck, and shoulders. Adjustable seats with lumbar support, armrests, and cushioning enhance operator comfort and reduce fatigue.

- Safe Access and Maintenance: Machine design incorporates features that facilitate safe access and maintenance procedures for operators, such as easily removable panels, safety interlocks, and lockout/tagout systems. Operators can access internal components and perform routine maintenance tasks without exposure to hazards or risks.

- Minimized Manual Handling: Wherever possible, wet wipes manufacturing machines are designed to minimize manual handling of heavy or awkward materials, components, or finished products. Automated material handling systems, conveyors, and robotics assist in loading, unloading, and transferring materials, reducing the risk of musculoskeletal injuries.

- Visual and Auditory Alerts: Machine design includes visual and auditory alert systems to notify operators of abnormal conditions, equipment malfunctions, or safety hazards. Clear, easily recognizable indicators and alarms help operators respond promptly to alerts and take appropriate corrective actions.

- Training and Ergonomic Awareness: Manufacturers provide comprehensive training and ergonomic awareness programs for operators to educate them on proper lifting techniques, workstation setup, and ergonomic principles. Training empowers operators to recognize ergonomic risks and implement ergonomic best practices in their daily work routines.

By integrating these ergonomic considerations into the design of wet wipes manufacturing machines, manufacturers can create a safer, more comfortable, and more efficient working environment for operators, ultimately enhancing productivity, quality, and employee satisfaction.